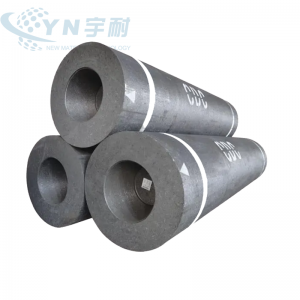

HP Graphite Electrode

Inkqubo yokuvelisa i-electrode yegraphite ngokubanzi ibandakanya: imathiriyeli ekrwada (uboya) → ukuxutywa → ukuxova → ukubumba i-extrusion → ubushushu obuphezulu be-sintering (1550~1700°C) + unyango lobushushu (1100~1200°C) + ukugqiba.

1. Ukulungiswa koboya: susa ukungcola eboyeni.Indlela ephambili yokungcola kukusebenzisa ukuhlamba kwamanzi okanye ukuhlamba i-alkali.

2. Izithako: Yongeza umlinganiselo othile wesanti yequartz xa uxova, uze ufake izinto ezixutywe ekrwada kwisixhobo sokuxova.

3. Ukuxova: Beka izinto ezixutywe ekrwada embindini we-graphite extruder, kwaye emva koko uxove kwaye ukhuphe imathiriyeli ekrwada ekrwada ukuze yenze kubumba lwegraphite.

4. Ukurosa: Tshisa izinto ezixutywe nelahle zibe bubushushu obubomvu okanye izinto ezinokutsha ezifana nekhabhoni emnyama kunye nomgubo wamalahle, uze ufake inkqubo elandelayo.

5. Ukugqiba: Emva kokuba i-mold yenziwe, kufuneka inqunywe, ifakwe i-welded, iphuculwe kunye nezinye iinkqubo.

6. Ukupakishwa: Iimolds kufuneka zihlolwe (kuquka ukucoceka kunye nokuba kukho nawuphi na umonakalo kunye nemikrwelo, njl. njl.) kwaye zihlelwe kwaye zipakishwe ngaphambi kokuba zigcinwe kwindawo yokugcina impahla.

Imisebenzi ye-carbonization charge layer yile: ukukhusela umrhumo kwi-oxidation kwiqondo lokushisa eliphezulu, ukwenzela ukuba kuqinisekiswe ukuba izinto zetsimbi kwi-slag aziyi kuguquguquka;ukugcina ukuncipha kwe-carbothermal reaction kwimo etyhidiweyo, ukuqinisekisa ukuba intlawulo iyanyibilika kwiqondo lobushushu kunye nexesha.

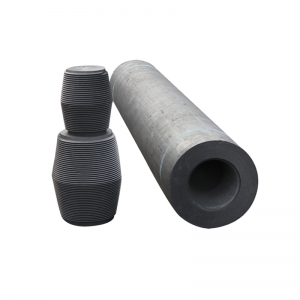

Umsebenzi ophambili wesithando sombane se-arc kukwazisa i-arc yombane kwintlawulo yokunyibilikisa izinto ezinyibilikayo ze-carbon steel kwi-alloy metal.Izinto ze-electrode zesithando sombane se-arc ngokuqhelekileyo yi-graphite electrode, i-anode kunye ne-cathode graphite.

Isithando somlilo seCarbonization: i-charcoal itshiswa kwiziko ukuze ivelise i-carbon kunye ne-oksijini, kwaye igesi ye-flue eyenziwe ingena echibini elityhidiweyo emva kokupholisa, kwaye intsimbi etyhidiweyo ikhutshwa ngaphandle kwangaxeshanye.

I-Rotary Kiln: I-kiln yokunciphisa isetyenziselwa inkqubo yokunyibilikisa ukunyibilikisa isinyithi okanye i-alloys.

Quote Now

Quote Now